Copper Wire Ampacity (Chassis Wiring, 60°C–90°C Insulation)

Units: AWG, Amps (approx.)

| AWG | Amps (approx) |

|---|---|

| 18 | 10 |

| 16 | 13 |

| 14 | 18 |

| 12 | 25 |

| 10 | 40 |

| 8 | 55 |

| 6 | 75 |

| 4 | 95 |

Values are rule-of-thumb for automotive chassis wiring with typical insulation. For continuous loads, use 80% of rating. For long runs, consider voltage drop.

Minimum Inside Bend Radius (Air Bend – Starting Points)

Units: Thickness (in), Min Inside Radius (in)

| Material | Thickness (in) | Min Inside Radius (in) |

|---|---|---|

| Mild Steel | 0.060 | 0.060 |

| Mild Steel | 0.120 | 0.120 |

| Aluminum 5052 | 0.063 | 0.050 |

| Aluminum 6061-T6 | 0.063 | 0.094 |

| Stainless 304 | 0.060 | 0.090 |

Tighter bends may crack or distort, especially for 6061-T6 and stainless. Use proper tooling; consider anneal or larger radius for cosmetic parts.

Sheet Metal Thickness (Gauge vs Thickness)

Units: Gauge, inches, millimeters

| Gauge | Steel (in) | Steel (mm) | Aluminum (in) | Aluminum (mm) |

|---|---|---|---|---|

| 20 | 0.036 | 0.91 | 0.032 | 0.81 |

| 18 | 0.048 | 1.22 | 0.040 | 1.02 |

| 16 | 0.060 | 1.52 | 0.050 | 1.27 |

| 14 | 0.075 | 1.90 | 0.064 | 1.63 |

| 12 | 0.105 | 2.67 | 0.081 | 2.06 |

| 10 | 0.135 | 3.43 | 0.102 | 2.59 |

Gauges are nominal; thickness varies by spec (CRS vs galvanized). Always measure for precision work.

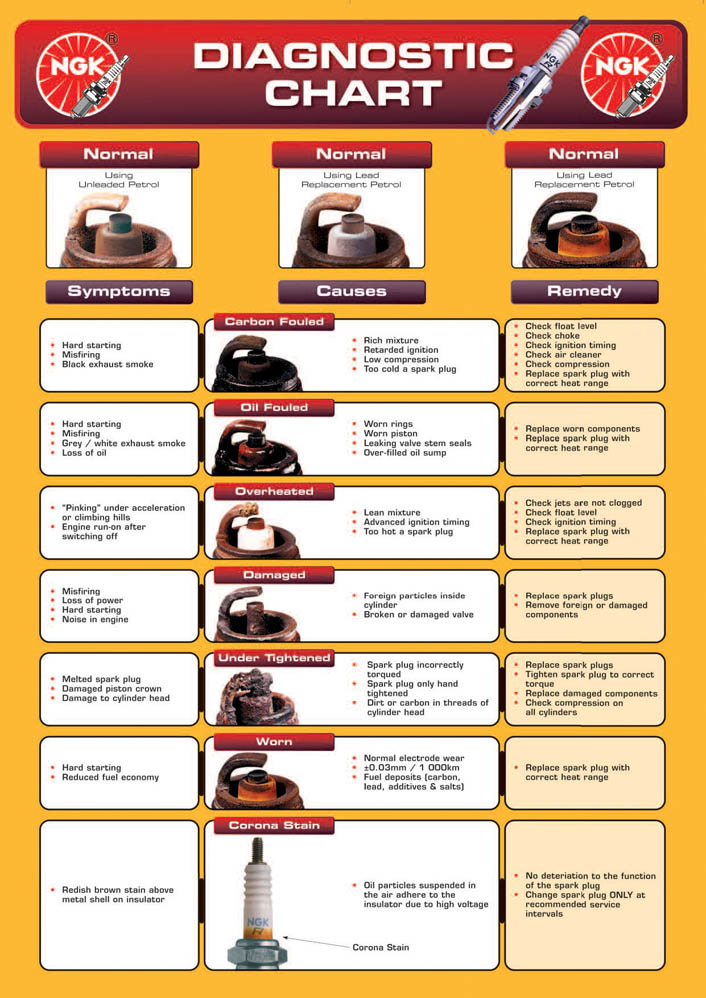

Spark Plug Condition Diagnosis Chart

Use this chart to interpret spark plug conditions. A light tan or gray plug usually indicates optimal combustion. Dark, wet, or oily plugs suggest issues such as rich mixture, oil control problems, or misfire. White or blistered plugs may indicate overheating, pre-ignition, or a lean mixture. Always compare against plugs from multiple cylinders and consider engine load and fuel type.

Warning: Cannot modify header information - headers already sent by (output started at /var/www/tools.pottsiesfab.com/public_html/charts/index.php:153) in /var/www/tools.pottsiesfab.com/public_html/charts/index.php on line 167

Warning: Cannot modify header information - headers already sent by (output started at /var/www/tools.pottsiesfab.com/public_html/charts/index.php:153) in /var/www/tools.pottsiesfab.com/public_html/charts/index.php on line 168

Thread,Pitch,Major Dia (in/mm),Drill Size,Drill Dia (in/mm),Series #4-40 UNC,40 TPI,0.1120 / 2.84,#43,0.0890 / 2.26,UNC #6-32 UNC,32 TPI,0.1380 / 3.51,#36,0.1065 / 2.71,UNC #8-32 UNC,32 TPI,0.1640 / 4.17,#29,0.1360 / 3.45,UNC #10-24 UNC,24 TPI,0.1900 / 4.83,#25,0.1495 / 3.80,UNC #10-32 UNF,32 TPI,0.1900 / 4.83,#21,0.1590 / 4.04,UNF 1/4-20 UNC,20 TPI,0.2500 / 6.35,#7,0.2010 / 5.11,UNC 1/4-28 UNF,28 TPI,0.2500 / 6.35,#3,0.2130 / 5.41,UNF 5/16-18 UNC,18 TPI,0.3125 / 7.94,F,0.2570 / 6.53,UNC 5/16-24 UNF,24 TPI,0.3125 / 7.94,I,0.2720 / 6.91,UNF 3/8-16 UNC,16 TPI,0.3750 / 9.53,5/16,0.3125 / 7.94,UNC 3/8-24 UNF,24 TPI,0.3750 / 9.53,Q,0.3320 / 8.43,UNF 1/2-13 UNC,13 TPI,0.5000 / 12.70,27/64,0.4219 / 10.72,UNC 1/2-20 UNF,20 TPI,0.5000 / 12.70,29/64,0.4531 / 11.51,UNF M3 x 0.5,0.50 mm,— / 3.00,2.5 mm,0.0984 / 2.50,Metric Coarse M4 x 0.7,0.70 mm,— / 4.00,3.3 mm,0.1299 / 3.30,Metric Coarse M5 x 0.8,0.80 mm,— / 5.00,4.2 mm,0.1654 / 4.20,Metric Coarse M6 x 1.0,1.00 mm,— / 6.00,5.0 mm,0.1969 / 5.00,Metric Coarse M8 x 1.25,1.25 mm,— / 8.00,6.8 mm,0.2677 / 6.80,Metric Coarse M10 x 1.5,1.50 mm,— / 10.00,8.5 mm,0.3346 / 8.50,Metric Coarse M12 x 1.75,1.75 mm,— / 12.00,10.2 mm,0.4016 / 10.20,Metric Coarse M8 x 1.0,1.00 mm,— / 8.00,7.0 mm,0.2756 / 7.00,Metric Fine M10 x 1.25,1.25 mm,— / 10.00,8.8 mm,0.3465 / 8.80,Metric Fine M12 x 1.5,1.50 mm,— / 12.00,10.5 mm,0.4134 / 10.50,Metric Fine